KaiwuDB has developed an all-in-one IIoT solution for all our customers in discrete manufacturing. We integrate multi-model data storage, in-data computing, cross-model analysis and high-ratio data compression into the solution and incorporate our data service platform KDP. With our KaiwuDB solution, our heavy industry customer is now able to perform data management throughout the lifecycle from data collection to intellectual analysis, laying a reliable digital foundation with stability, efficiency and intelligence.

The heavy industry group has been internationally renowned for its automobile and equipment manufacturering. It built up a SCADA(Supervisory Control and Data Acquisition) system to support data acquisition, data push, data analysis and other functions in the production process, which has to collect data from more than 5,000 terminal devices that produce 100 million data records every day. As business growing, the original MySQL database depolyed in the SCADA system can no longer meet the data needs, while problems in production management are crucial.

1. Difficulty in multi-model data collection.Data collection devices use many types of protocols such as Modbus and LoRa, which produce multi-model data such as time series data, relational data and others.

2. Difficulty in data value realization.The SCADA system supports data acquisition and storage, but cannot afford data analysis and subsequent development and utilization.

3. Difficulty in multi-DB dev-ops.The SCADA system adopted multi-DB deployment to cope with multi-model data needs, which is lack of scalability and asks for high investment in dev-ops personnel.

4. Difficulty in production process supervision.The equipment status feedback relies on manual statistics, so the production process is not transparent. Workers falsely report working-hours, resulting in a decrease in production capacity.

5. Difficulty in production scheduling. Without data support, the production line scheduling and delivery dates relies on subjective speculation. The equipment and workload scheduling are unreasonable.

6. Difficulty in equipment failure warning. Without early warning about equipment status and maintenance, the factory cannot avoid sudden faults in the production line. Unplanned downtime directly affects production capacity.

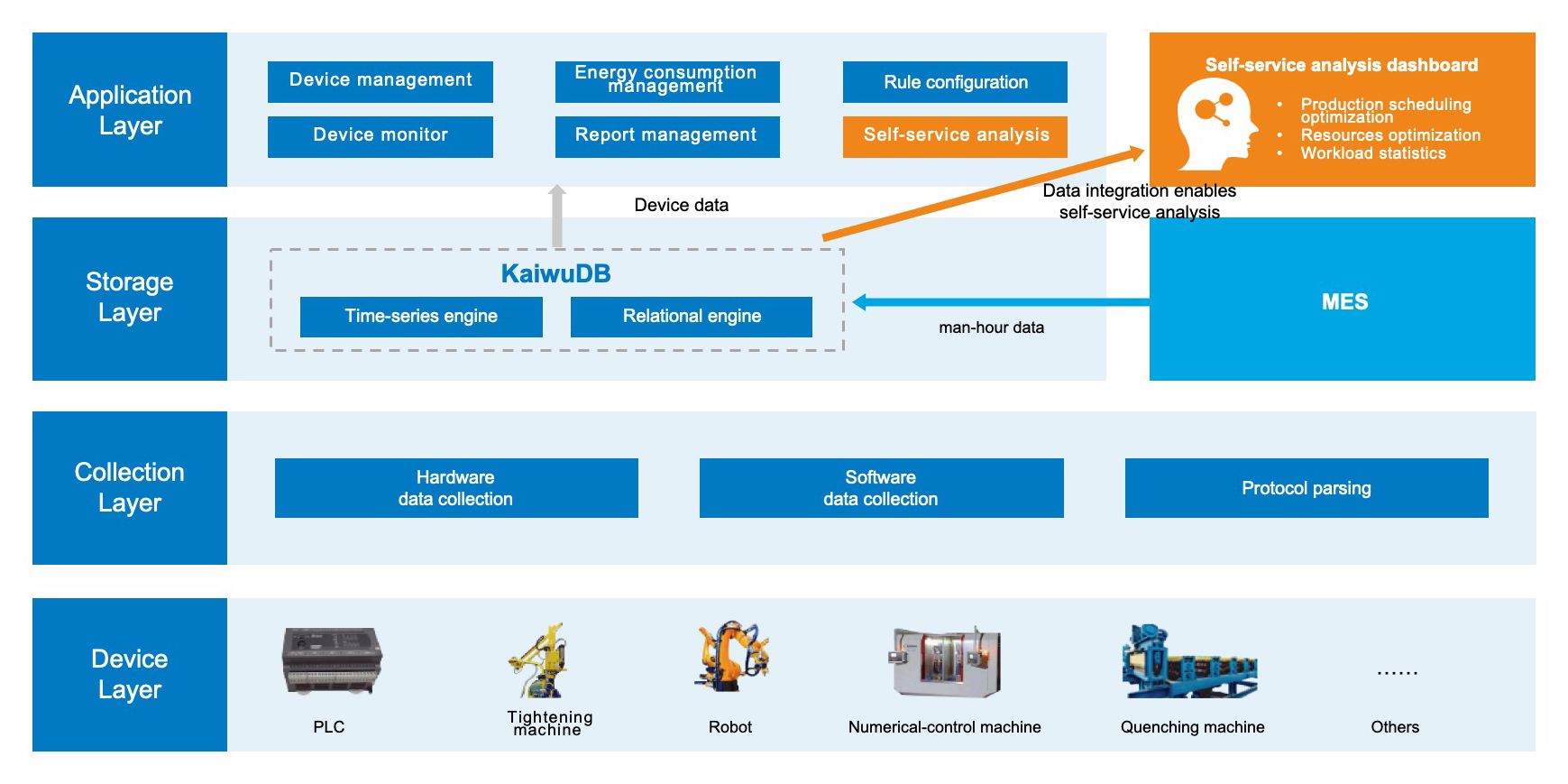

To cope with data management difficulties faced by the heavy industry group, we have developed a one-stop IIoT solution for discrete manufacturing industry based on our multi-model database KaiwuDB and data platform. Relying on core techniques such as multi-model data storage, in-data computing, cross-model analysis and data compression, the IIoT solution offers a lifecycle data management from collection to analysis, helping the factory build an efficient, stable, and intelligent digital foundation.

Data Collection: Compatible with multiple industrial protocols and support multi-model data integration; support smooth data migration from existing databases.

Data Processing: Relyed on KaiwuDB's core technique in-data computing and stream-calculation, the real-time data analysis supports production line evaluation, equipement failure warning and other decision-making scenarios.

Data Display: Offer visual report management and self-service results presentation; enable indicators monitoring through self-service analysis dashboard.

1. "One platform"

Through KaiwuDB data platform, the SCADA system relized an aggregated processing of multi-source data collected from 100,000 + collection points on 2,000+ equipment such as PLC, numerical control machine, tightening machine, quenching machine, robot, filling machine and others.

2. "Two ‘Ups‘"

1) Data writing performance is up 2-8 times. And we can write up to 10 million data records per second.

2) Aggregated analysis in complex scenarios is up 10% -30%.

3. Benefit from the above data capabilities, our customer's equipment failure rate is reduced by 65% while the utilization rate is increased by 20%. Processing efficiency is increased by 20%, and equipment investment costs are reduced by 10%. At the same time, KaiwuDB Data Platform enabled a data sharing between frontline production and upper-level business operation, laying a solid foundation for data assetization and data sharing mechanisms.