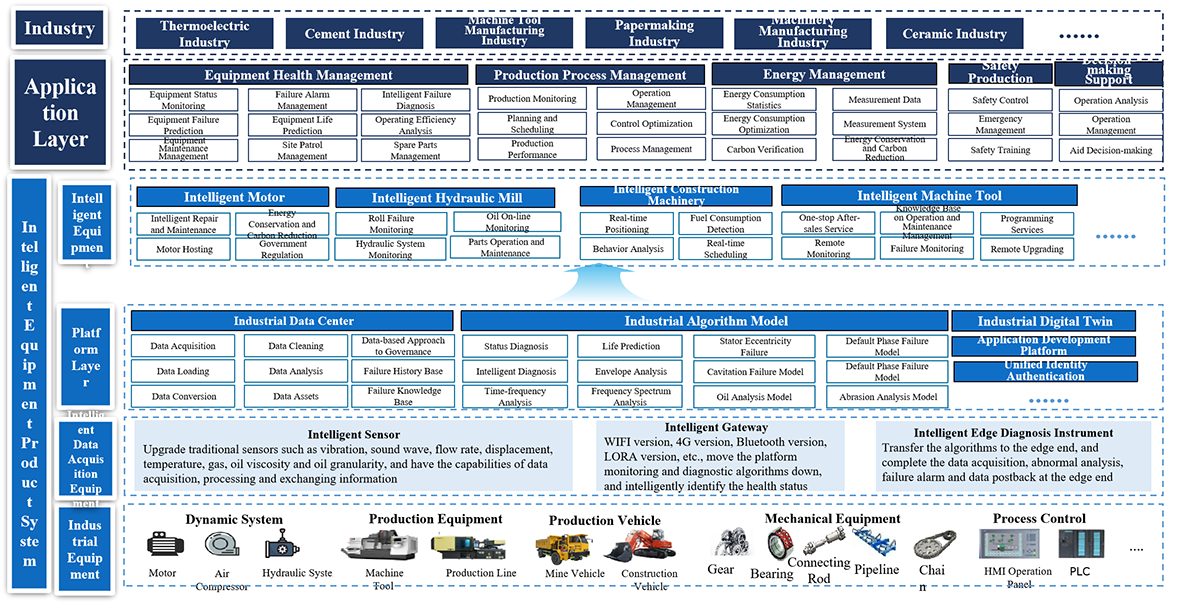

Based on the Internet of Things (IoT), through intelligent acquisition terminals, driven by the monitoring data of industrial equipment operation status, we use cutting-edge technologies such as big data and digital twin to realize the rapid processing of equipment monitoring data, automatic discrimination and push of abnormal conditions and other functions, and conduct predictive maintenance services, so as to help enterprises to decrease costs and increase benefits.

Software and Hardware Integration

With “Machine Vibration+Mechanism Model+Algorithm” as the technical core, we create a product system of “Product+Platform+Service” software and hardware integration.

Mechanism Model

We are deeply involved in the industrial field to create an integrated industrial mechanism knowledge, expert experience and machine learning algorithm, and provide data processing, model development, model training, model assessment, model management and model application.

Expert Guidance

Based on the diagnosis results, we rely on process and equipment experts to provide technological reform and remote guidance and other services.

Production Line Level Operation Pattern

We unify the control standards for the equipment status of production lines to realize the consistency between equipment data and technical specifications.

Transforming Traditional Operation&Maintenance Pattern

We intelligently acquire the status data of rolling lines, use the failure mechanism model to monitor the remote operation and maintenance online, and accurately diagnose and predict the equipment failure.

Transforming Traditional Employment Pattern

Based on the establishment of industry knowledge graph, we have formed a talent training system with “Intelligent Maintenance Engineer” and “Diagnostic Analyst” as the core.