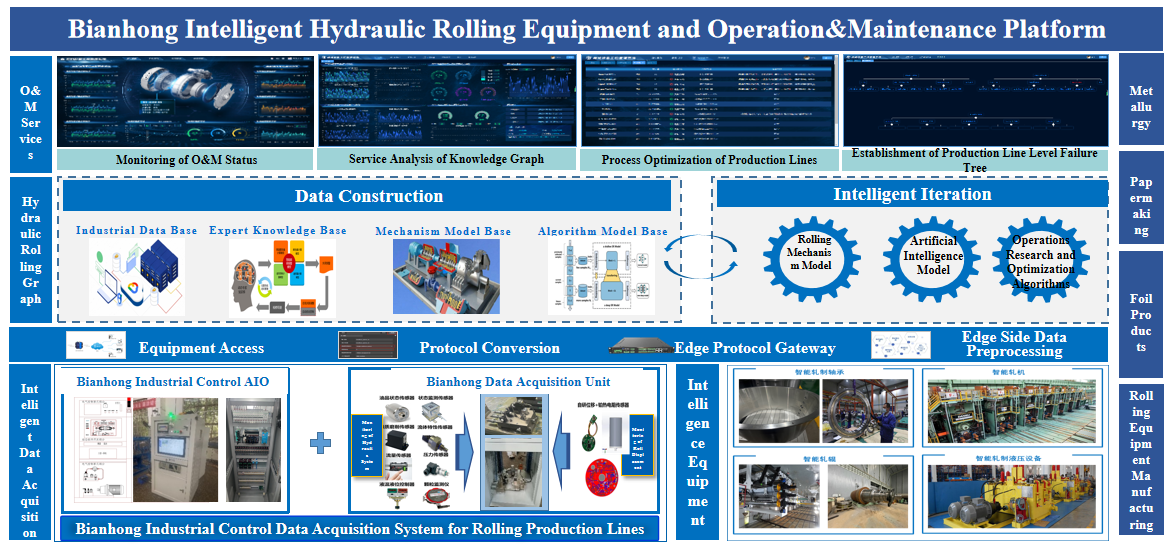

Under the scenario of industrial hydraulic rolling, we construct an operation and maintenance system for data acquisition of production line level, data analysis and control of edge sides, dynamic regulation and autonomous optimization iteration from three dimensions: data perception, graph establishment, operation and maintenance and optimization control, so as to realize the intelligent upgrading of the rolling industry.

It mainly includes two parts: intelligent data acquisition equipment and operation and maintenance platform. The intelligent data acquisition equipment mainly includes various self-developed sensors, data acquisition integration units and industrial control computer systems, which are used to acquire various data such as temperature, vibration and oil status of hydraulic pressure and rolling line. It has functions such as man-machine interaction, monitoring of operation status, parameter settings and display of failure alarm information, and reserves communication interfaces with external sensors and PLC. The operation and maintenance platform is based on the intelligent iterative knowledge graph, which mainly has functions such as monitoring of operation and maintenance status, service analysis of knowledge graph, failure tree of production line level and process optimization.

1.Production Line Level Operation Pattern

We unify the control standards for the equipment status of production lines to realize the consistency between equipment data and technical specifications;

2.Transforming Traditional Operation&Maintenance Pattern

We intelligently acquire the status data of rolling lines, use the failure mechanism model to monitor the remote operation and maintenance online, and accurately diagnose and predict the equipment failure;

3.Transforming Traditional Employment Pattern

Based on the establishment of industry knowledge graph, we have formed a talent training system with “Intelligent Maintenance Engineer” and “Diagnostic Analyst” as the core.