Based on the Internet of Things (IoT), with machine vibration+mechanism model+algorithm as the technical core, we create a product system of “Product+Platform+Service” software and hardware integration to provide customers with equipment monitoring, diagnosis, life prediction and other services.

I. Product Overview

Based on the monitoring data of industrial equipment operation status, we use cutting-edge technologies such as big data and digital twin to realize the rapid processing of equipment monitoring data, automatic discrimination and push of abnormal conditions, early prediction of failure volution trends and intelligent formulation of maintenance strategies, so as to conduct predictive maintenance services for the manufacturing industry, reduce the equipment operation and maintenance costs of enterprises, and enhance the economic benefits.

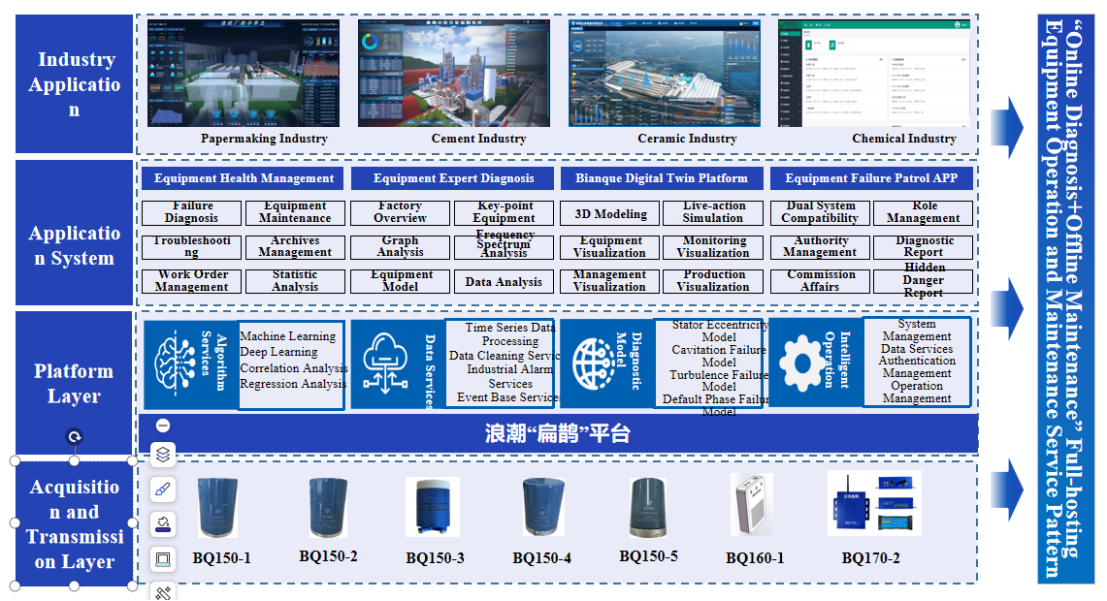

II. Product Architecture

Data Acquisition Layer: It mainly realizes the data acquisition function of on-line monitoring of equipment status, data acquisition function of offline equipment status and data acquisition and access function of third-party monitoring systems (such as DCS systems). The data acquisition of offline equipment status is to link the movable vibration and temperature sensors with the site patrol detector, and acquire the data of equipment operation status. After the acquired data results are uploaded to the system, the equipment failures or failure risks can be analyzed and diagnosed.

Data Transmission Layer and Storage Layer: It mainly realizes the network channels for data transmission and interaction, including wired and wireless (WiFi, 3G and 4G) forms. The data storage layer realizes the effective data storage function and reserves the data interface, which can realize the open equipment big data center in the enterprise and avoid the information isolated island.

Analysis Model Layer: It includes various thematic analysis models, algorithm pools in the algorithm base, feature sets, model bases, feature extraction, model matching, deep analysis, machine learning and other functions. The layer is the core layer of intelligent equipment management. The models and algorithms in the layer complete the analysis, diagnosis and prediction of equipment failures, and the machine learning continuously enriches the model algorithm base through the diagnosis and prediction results, and enhances the accuracy of diagnosis and prediction.

Application Module Layer: It includes asset management, equipment health management (real-time equipment monitoring, equipment failure diagnosis and equipment health analysis, etc.), site patrol management, maintenance management, repair management, spare parts management, energy management (energy monitoring, energy statistics and energy performance configuration), cockpit management, 3D virtual factory (virtuality and reality combination of equipment), alarm notification, knowledge management, system management and other functions, so as to provide interactive support for users.

III. Product Functions

Intelligent Sensor: The intelligent sensor developed, designed and contract manufactured by Inspur can acquire data such as vibration (uniaxial or multi-axial acceleration), temperature and magnetic flux, which is widely used in status monitoring and failure diagnosis analysis of various industrial key small equipment such as motors, pumps and bearings.

Equipment Health Diagnosis: Based on the complete sensing mechanism, we rely on intelligent algorithms, big data analysis and other technical means to provide online monitoring and intelligent diagnosis services for various types of small equipment in the industrial manufacturing process, ensure the equipment health and enhance the manufacturing efficiency.

Diagnostic Report Services: We have senior equipment diagnostic experts who can provide remote diagnostic services for users, help enterprises to diagnose potential equipment failures and propose optimization suggestions.

Bianque Brain: We can realize the real-time connection of multi-source equipment, heterogeneous systems, people and other elements through many links, such as multi-type industrial equipment access, various industrial communication network protocol analysis, multi-source industrial data format conversion and real-time industrial data storage and preprocessing; meanwhile, various algorithms and application models for Bianque Brain internal integrated equipment can quickly diagnose equipment failures.

Software and Hardware Integration

With “Machine Vibration+Mechanism Model+Algorithm” as the technical core, we create a product system of “Product+Platform+Service” software and hardware integration.

Mechanism Model

We are deeply involved in the industrial field to create an integrated industrial mechanism knowledge, expert experience and machine learning algorithm, and provide data processing, model development, model training, model assessment, model management and model application.

Expert Guidance

Based on the diagnosis results, we rely on process and equipment experts to provide technological reform, remote guidance and other services.

Sensor Plug-in

Without equipment transformation, we acquire the equipment operation data and monitor the equipment operation status by means of sensor plug-in.