We tailor-made a digital energy management platform for Chery factory based on our distributed multi-model database KaiwuDB and data service platform KDP. Our in-data computing technology and KDP analysis enables real-time monitoring of the energy platform and AI-assisted decision-making for the management team. We have helped Chery Tsingdao factory significanlty improve their production efficiency and achieve visualized, digitized and refined energy management.

As one of Chery Automobile's highest-level digital factories, Chery Tsingdao Super Factory faces three major difficulties: massive energy consumption, considerable energy cost, and without unified energy management, which proposed challenges to its energy management platform. Meanwhile, in order to better respond to China's Double-Carbon Policy(carbon neutrality and peak carbon dioxide emissions), an ecological, sustainable industrial structure that reduces costs, increases efficiency is urgently needed. However, problems with massive data storage and data query frequently occur.

1. Difficulty in massive data storage

There are various energy monitoring equipment for water, electricity, gas, heating and other categories, as well as meteorological parameters in the factory, which require massive historical data storage for the past 10 years, posting challenges in data integration and cost reduction.

2. Slow response in data queries

Real-time queries of energy consumption in production line, and aggregated queries in multiple scenarios have to be responded in milli-seconds. The traditional database cannot afford daily query requirements.

3. Weakness in data mining and presentation

Energy management and control of Chery factory covers electricity, gas, water and multiple dimensions. Analytic results of a single dimension are difficult to support energy distribution decisions. Meanwhile, the traditional database shows weakness in report export, which only supports Excel presentation.

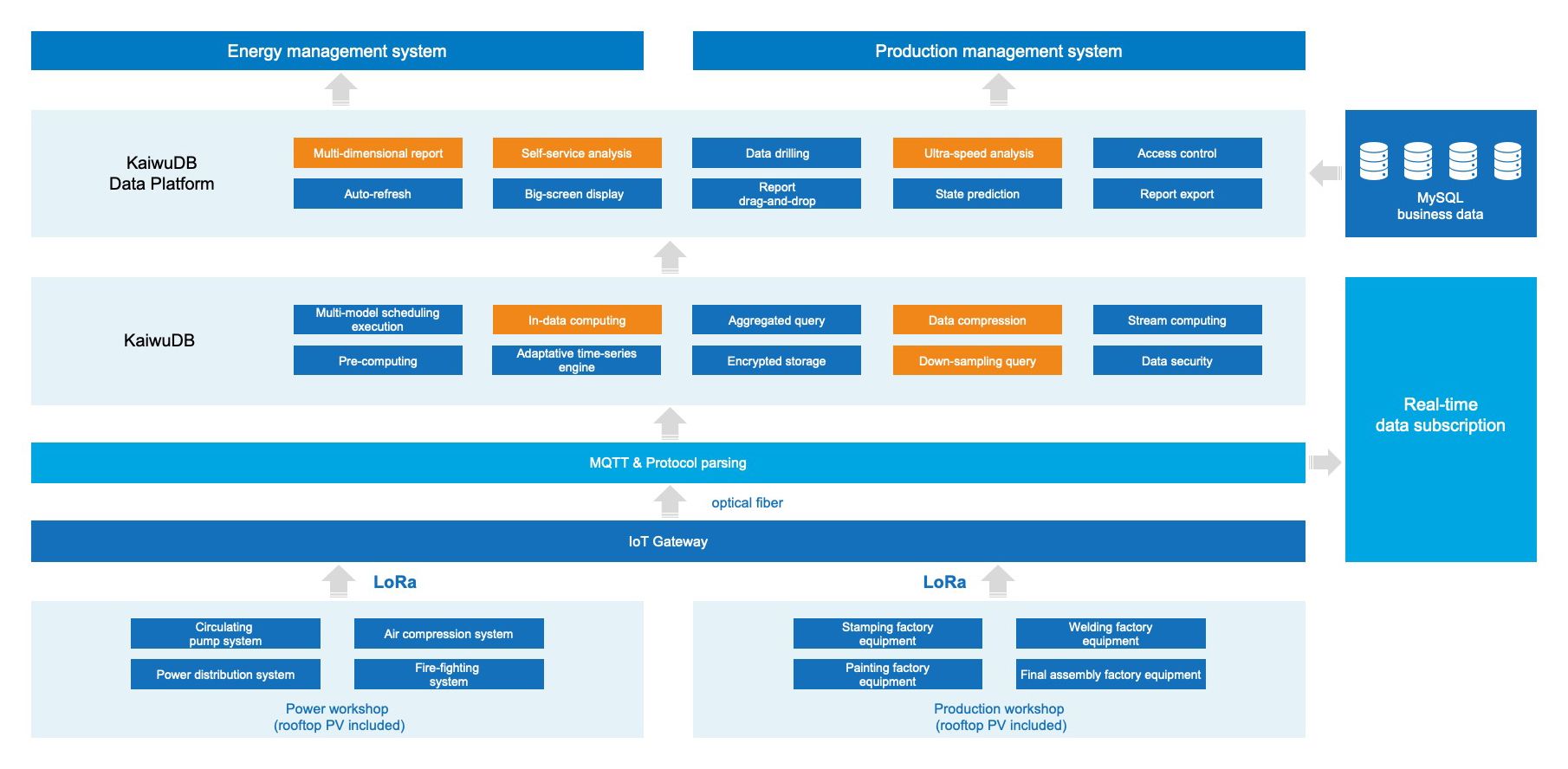

To deal with the energy management challenges of Chery factory, we offered a targeted solution by building a comprehensive digital energy management platform based on our multi-model database KaiwuDB and Data Platform.

KaiwuDB's high compression capability solved the problem of massive data storage and high cost posted by data from more than 100,000 measuring points. As a core technique, in-data computing fully supported real-time monitoring, and multi-source data analysis of key scenarios.

Benefit from the analysis capabilities of KaiwuDB Data Platform, the energy management platform achieves drill-down analysis of data with 20 dimensions times 20 levels, providing nearly 40 display forms for basic charts. At the same time, it supports joint analysis of multi-model data such as electricity, heating, and compressed gas, assisting decision-making in multi-dimensions, improving production efficiency and achieving a "visualized, digitized, and refined" energy management.

1. Two major efficiency improvements

Realized high-speed data writing of 11 million new data collected from 30,000 measuring points every day, covering multiple data categories such as water, electricity, gas, heat and equipment status. Thus helped he factory achieve centralized management of massive data on the energy management platform.With high-speed aggregated analysis, down-sampling storage and complex queries, the platform achieved a maximum of 20 million data query in 150ms, and 800,000 data processing in one second, ensuring a safe and stable operation of energy monitor and extended the equipment life.

2. Two major cost reductions

Saving energy by 15% -20% and reducing the cost by RMB7-10 million yuan per year. The construction of energy management platform greatly reduces the industrial park management difficulties and costs;The overall data compression performance is 10 times and more, together with tiered storage of cold and hot data, the platform achieved a data lifecycle management while significantly saved costs.