Inspur has the largest market share in the digitalization market in China's grain industry. Inspur's grain depot construction and electromechanical integration solutions focus on the main needs of depot type selection, electromechanical and automatic control equipment installation, commissioning, integration and service during the construction of new grain depots. Based on the successful construction experience in Hebei, Fujian, Guangdong, Shandong and Jiangsu provinces in China, combined with the excellent equipment supply of industry ecosystem manufacturers, and using advanced technology, processes and high construction standards, we specifically solve problems for customers with depot construction needs, directly address customers' pain points, and gradually become mature and form the Inspur's grain depot construction and electromechanical integration solutions that cover the entire process of grain depot construction, grain unloading, lifting, conveying, grain cleaning, warehousing and distribution, thereby serving the global grain depot infrastructure construction and ensuring global grain security.

International Environment

1.The global grain supply and demand situation is becoming tense. According to the latest report released by the World Bank, the epidemic and the Russia-Ukraine conflict have exacerbated global grain security risks. It is estimated that millions of people around the world will suffer from a serious grain crisis and the global grain supply chain will be further hindered.

2.The global grain storage market shows a booming trend, with the market size increasing year by year. From a regional perspective, the grain storage market is relatively mature in Europe and the United States, where the level of agricultural modernization is relatively high. In the future, in countries and regions such as Asia, Africa, and Latin America, which have a relatively low level of agricultural modernization, high population growth rate, and large demand for grain storage, will have a huge demand for grain depot infrastructure.

3.In September 2013 and October 2013, Chinese President Xi Jinping proposed the cooperation initiatives of building the "Silk Road Economic Belt" and the "21st Century Maritime Silk Road" respectively. As of the end of June 2023, China has signed more than 230 cooperation documents on jointly building the Belt and Road Initiative with more than 150 countries and more than 30 international organizations. China's collaborative development with Belt and Road countries enjoys a robust growth.

Industry Development Pain Points

1.The infrastructure level of grain depots is low, while a large number of traditional grain depots have poor insulation and airtightness, low mechanical automation level, poor grain storage and preservation level, and high grain loss;

2.The construction of new reinforced concrete grain depots requires large investments and a long construction period. The construction is difficult to carry out, and it is highly dependent on topography and soil conditions;

3.The level of mechanical automation of grain in and out of depot is low, and the operation relies heavily on manual labor, resulting in low efficiency and high operating costs;

4.Traditional grain depot operation methods cause heavy dust pollution and are not environmentally friendly;

5.Traditional grain depot operation methods cause frequent production safety accidents.

Inspur's grain depot construction and electromechanical integration solutions are aimed at government agencies, grain and oil companies or private grain depot owners who have the need to build new grain depots. Advanced technology, processes, products and professional construction and installation services are adopted to provide them with a safe and efficient new generation of modernized grain depot construction and electromechanical integration solutions.

Inspur’s grain depot construction solution mainly include depot made of steel and depot made of air film. Due to the limitations of terrain and climate conditions, Africa and the Middle East are dry and water-scarce all year round. Deserts and grasslands account for a large proportion of the landforms, making it difficult to build grain depots. Air film and steel depots effectively solve such problems. The air film depot has made innovations in fire protection design, depot type selection, structural optimization, process improvement, and new equipment research and development. It has increased the height of the straight section for loading grain, minimized the dome height (radius vector ratio), conducted special research on the pre-reserving and pre-burying required in the grain storage process, and solved the construction technology difficulties.

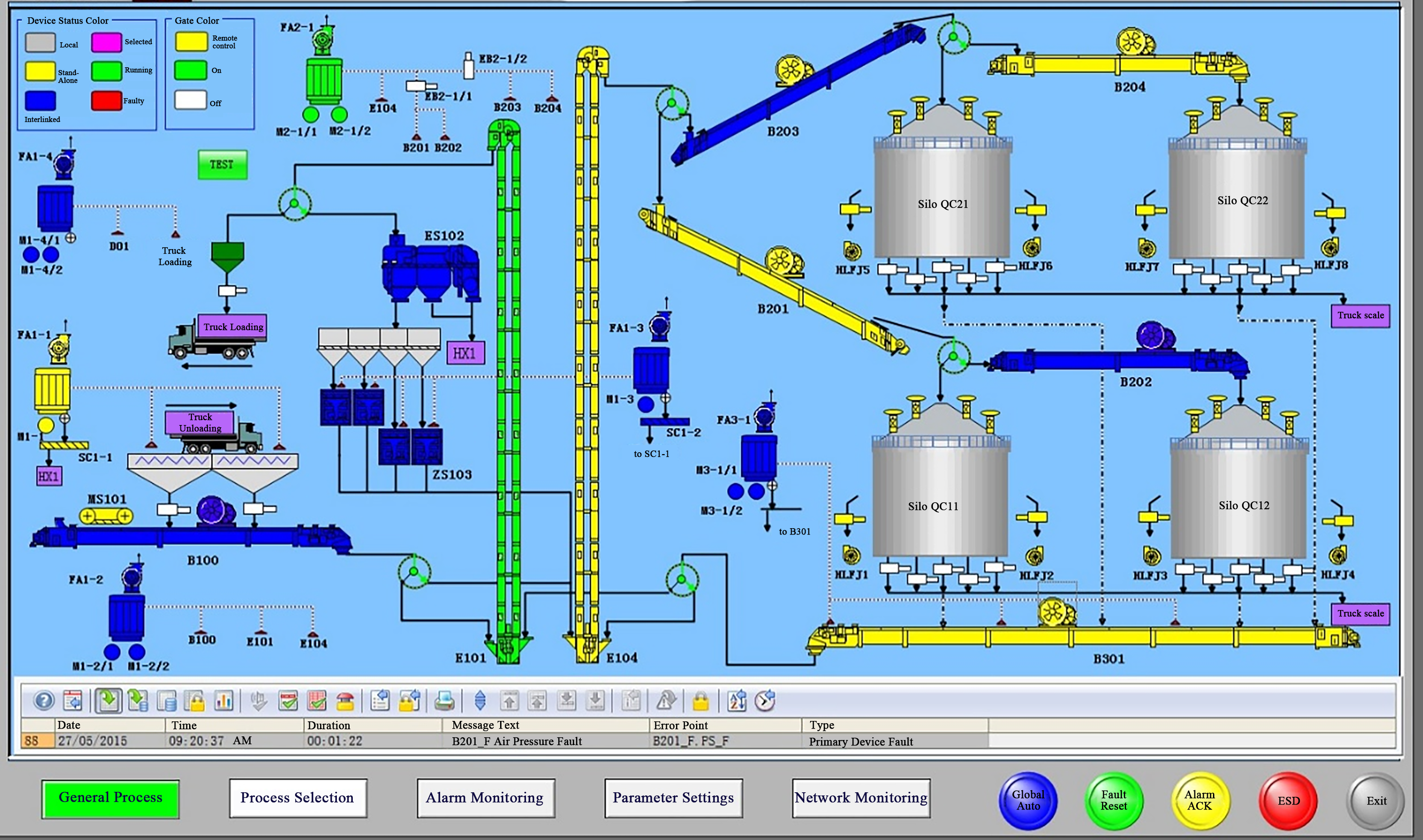

Inspur's electromechanical integration solution for grain depots covers the installation, commissioning and operation and maintenance services of mechanical, electrical and automated control systems for the entire process of grain unloading, lifting, cleaning, purification, conveying, warehousing and distribution. It eliminates the risks of low grain depot operation efficiency, high operating costs, and frequent production safety accidents. At the same time, the entire process of entering and leaving the depot can be set according to user needs, and the operator can check the entire situation remotely without going to the site. Equipped with monitoring equipment, sensors and alarm devices, early warning of possible production safety accidents can be given, making it truly safe, efficient and fully automatic.

1.Lower grain loss rate: Compared with traditional grain depots, air film depots have better thermal insulation performance. The outer film material has a reflective function, and the thermal insulation layer is integrated with the waterproof layer and the structural layer. The temperature and humidity in the depot are basically constant, further improving the quality of grain storage. Large steel depots have excellent sealing performance and humidity control systems. The higher air tightness and thermal insulation of the two types of depots can reduce the moisture absorption rate of grains, the risks of pests and mildew, effectively reduce the loss rate of grains, and ensure the quality and safety of grains;

2.More reliable waterproof performance: In Africa and the Middle East, there are distinct dry and rainy seasons. In the rainy season, if the grain depot has poor waterproof performance, it is easy for water to enter and soak the grains. Air film depots and steel depots solve this problem well.

3.Lower economic cost: Compared with traditional grain storage facilities, large steel depots and air film depots take less time to build. The steel plates adopt prefabricated assembled structures, and most of the manufacturing work can be completed in the factory. After being exported to the destination country, they are assembled on site. The entire construction process of the air film depot is carried out inside the air film, which can achieve environmentally friendly and efficient all-weather interference-free construction. Both of the two methods can greatly shorten the construction period. After completion, it does not require frequent maintenance and repairs, saving valuable time and economic costs for grain depot operators;

4.Higher degree of environmental protection and energy saving: The grain depot construction and electromechanical integration solutions adopt advanced dust removal technology and has great sealing performance, which can reduce the generation and spread of dust and protect the surrounding environment from pollution. At the same time, its excellent energy-saving performance can reduce energy consumption and waste, which is in line with the current development trend of the international community's increasing attention to environmental protection and energy conservation.

Depot type products of grain depot construction

Steel depot unloading, conveying and lifting equipment

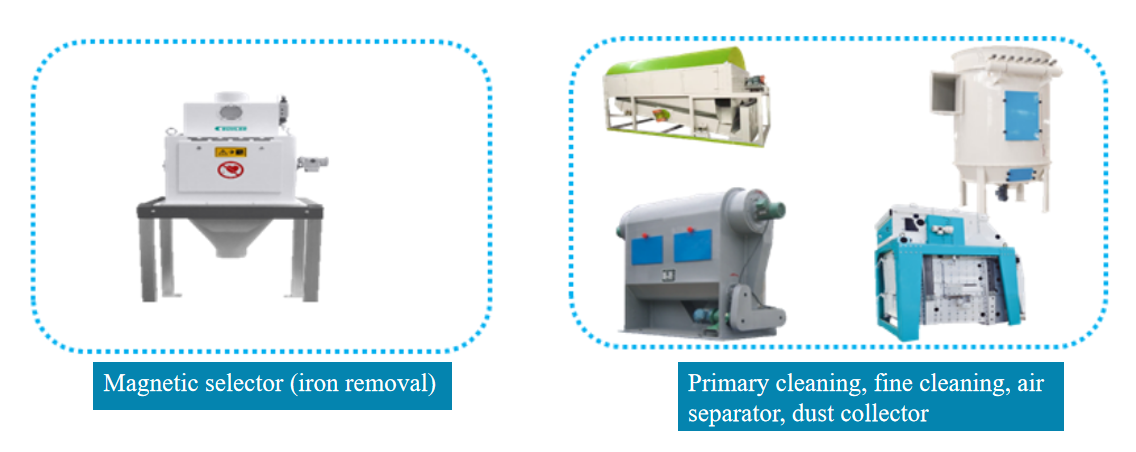

Cleaning and grain purification equipment

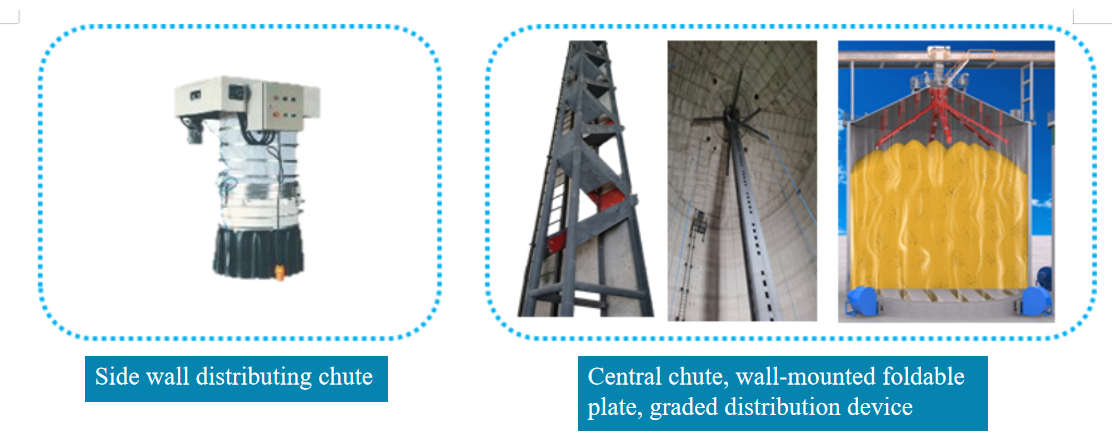

Warehousing and distribution equipment

Electrical automatic control system process