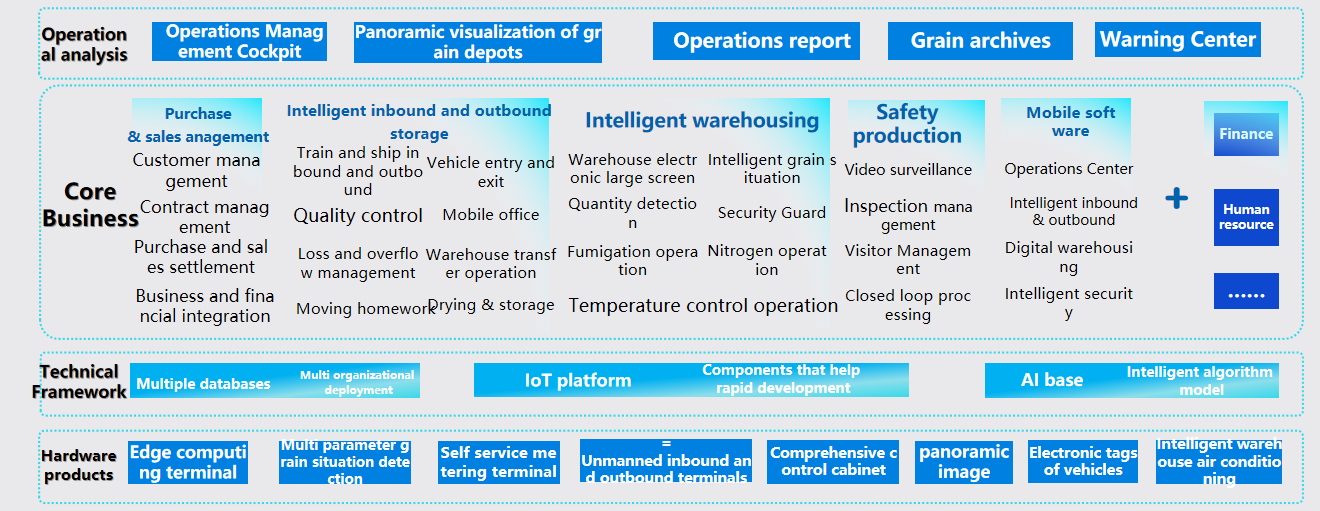

Inspur's Intelligent Grain Depot solution utilizes new-generation digital technologies such as the Internet of Things (IoTs), artificial intelligence (AI), big data, digital twins, and biological recognition. Taking "grain warehousing" as the center, the solution covers the complete business chain from inbound warehouse, and warehousing, to outbound warehouse. Upon data integration, analysis, and processing, it provides an intelligent and integrated management platform for agricultural and grain-related enterprises. By establishing various standard business processes with higher operational efficiency, and automatic operation workflows for warehouse-in/out, warehousing, and transfer, the solution helps grain companies take all aspects under control through clear instructions, transparent information, and remote visualization.

International Environment

1.Currently, the global grain supply and demand situation is still tense. According to the latest report released by the World Bank, the epidemic and the Russia-Ukraine conflict have exacerbated global grain security risks. It is estimated that millions of people around the world will suffer from a serious grain crisis and the global grain supply chain will be further hindered.

2.The global grain storage market shows a booming trend, with the market size increasing year by year. From a regional perspective, the grain storage market is relatively mature in Europe and the United States, where agricultural modernization is relatively high. In the future, the main growth drivers of the global grain storage market will come from Asia, Africa, and some other countries and regions with low agricultural modernization, high population growth rates, and large demands for grain storage.

3.In September 2013 and October 2013, Chinese President Xi Jinping proposed the cooperation initiatives of building the "Silk Road Economic Belt" and the "21st Century Maritime Silk Road" respectively. As of the end of June 2023, China has signed more than 230 cooperation documents on jointly building the Belt and Road Initiative with more than 150 countries and more than 30 international organizations. China's collaborative development with Belt and Road countries enjoys a robust growth.

Industry Development Pain Points

1.Most grain warehousing businesses use traditional manual operations with low efficiency and insufficient automation.

2.Most grain business operations are handled manually, with only printed summary statistics for daily operations, resulting in digital poverty in overall business management.

3.Information is not transparent across all grain purchasing links, leading to low collaboration efficiency.

4.Most grain warehousing storage operations are operated manually, lacking the complete grain storage operation mechanism and adequate management.

5.The technical protection for work safety is poor. Workers may encounter hazards when entering and exiting silos or fumigating grains. The safety technical measures are inadequate. All these make it impossible for real-time monitoring and prevention of work safety-related accidents.

With the advent of the new technological wave represented by the "Internet +", new opportunities emerged, allowing the grain industry to transform, grain markets to innovate their supervision and control policies, and grain companies to employ novel grain warehousing management approaches. Over the past few years, the global grain industry has undergone informationization mainly in operation automation, intelligent warehouse-in/out and warehousing, and business management visualization. As a result, we have seen remarkable progress in certain areas. Conventional grain depots have been upgraded to digital ones, and many are striving to become smart or intelligent grain depots.

Inspur has been exploring and accumulating experience in the field of informationization of the grain industry for many years. It has a deep understanding of grain administration systems, reserve grain management, and the operational processes and management challenges of grain-related enterprises. By summarizing, accumulating, and utilizing its rich experience in informationization of the grain industry, Inspur has engaged in various related fields, such as grain big data, intelligent operation decision-making, reserve grain business management, grain purchasing and storage management, grain fund management, grain quality traceability, intelligent grain depot construction, intelligent warehousing transformation, remote administrative supervision, e-government, mobile applications, and system integration. By fully integrating its various independent scientific and technological innovations, and relying on its strong strength in cloud computing and big data, in response to the government's call, Inspur launched the "Inspur Intelligent Grain Depot Solution", an innovative informationization outcome for the grain industry in the "Internet +" era.

Inspur's Intelligent Grain Depot solution utilizes new-generation digital technologies such as the Internet of Things (IoTs), artificial intelligence (AI), big data, digital twins, and biological recognition. Taking "grain warehousing" as the center, the solution covers the complete business chain from inbound warehouse, and warehousing, to outbound warehouse. Upon data integration, analysis, and processing, it provides an intelligent and integrated management platform for agricultural and grain-related enterprises. By establishing various standard business processes with higher operational efficiency, and automatic operation workflows for warehouse-in/out, warehousing, and transfer, the solution helps grain companies take all aspects under control through clear instructions, transparent information, and remote visualization.

Inspur's products cover the IoTs, Internet, automated control, information acquisition, real scenario simulation, big data mining, and business intelligence technologies, helping create a regional or group-based, open, integrated intelligent service center. Inspur's target group covers grain administrative departments, grain warehousing, processing, and logistics enterprises, and relevant regulatory agencies. Inspur provides them with all-round services, such as comprehensive decision-making, intelligent monitoring and early warning, remote supervision and dispatching, information standardization, grain depot operation and management, warehousing management, quality and safety management, intelligent warehousing, intelligent warehouse-in/out management, intelligent security, grain condition monitoring, report statistics, information sharing and dissemination, and online business collaboration.

1.Business integration and chain forming, and purchase-sales-storage integration: Taking grain circulation as the basic line, Inspur's solution covers the entire life cycle of grain depots, from purchase and inbound warehouse to storage, and finally to sales and delivery, integrating purchase, sales, and storage of grains in the grain depot.

2.Data interconnection and intelligent analysis and decision-making: Inspur's solution integrates various systems and devices for grain condition detection, quantity monitoring, insect condition monitoring, nitrogen injection control, intelligent ventilation, intelligent security, and environmental monitoring. It enables automatic data acquisition to build a professional intelligent warehousing operation analysis model and visualize deliverables in a variety of ways such as tables, graphics, videos, and audio. The solution enables automatic warehousing management through real-time monitoring of grain conditions, climate environment, and grain quantity changes around the clock, automatic decision-making, intelligent analysis, quick grain preservation planning, and automatic on/off switch of related warehousing equipment.

3.Real-time early warning and supervision to ensure work safety: By comparing and analyzing information such as vehicle operation data and vehicle history, Inspur's solution can effectively identify abnormal vehicle operation data in systems, and timely give early warnings for abnormal vehicle tare weight and similar data. This reminds users to respond to abnormalities as soon as possible, and promptly eliminate illegal and cheating behaviors to ensure work safety.

4.Operation standardization to improve management norms: Through the interconnection of IoT terminal devices and information sharing across links, Inspur's solution visualizes the warehouse-in/out operation supervision, helping establish unified business processes and information standards for reserves, purchases and sales, warehousing, and finance. This achieves the purchase-storage-sales integration, scheduling-execution integration, business-finance integration, and money-grain integration by improving the business cooperation efficiency of various departments, reducing business risks, and lowering operating costs.

5.Innovative mobile applications to improve work efficiency: In Inspur's solution, mobile applications are used for supervision information viewing, business handling, and data entry anytime, anywhere. They make it easier to understand the business operation data and development in real time. Through remote supervision, warehouse inspection, and image capture for traceability, these mobile applications also help user effectively integrate their fragmented working hours and improve their productivity.

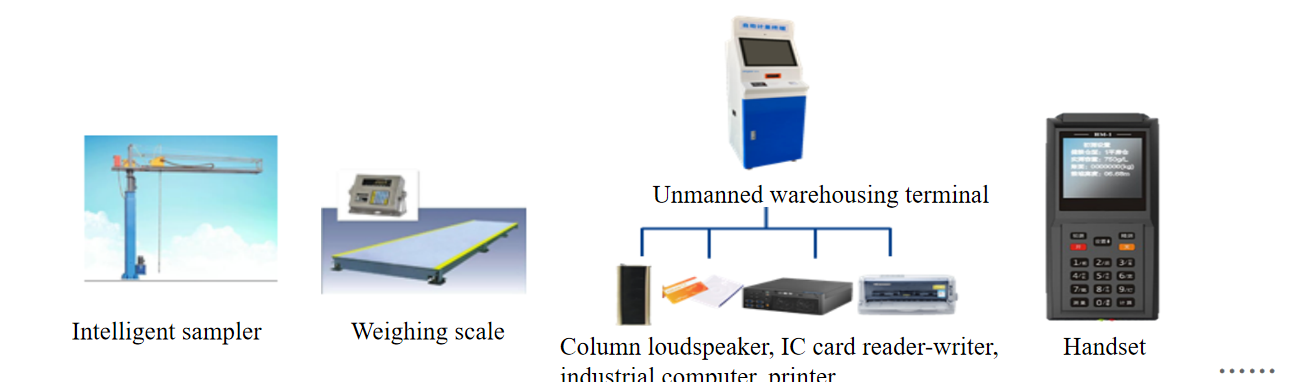

Warehouse-In/Out Systems

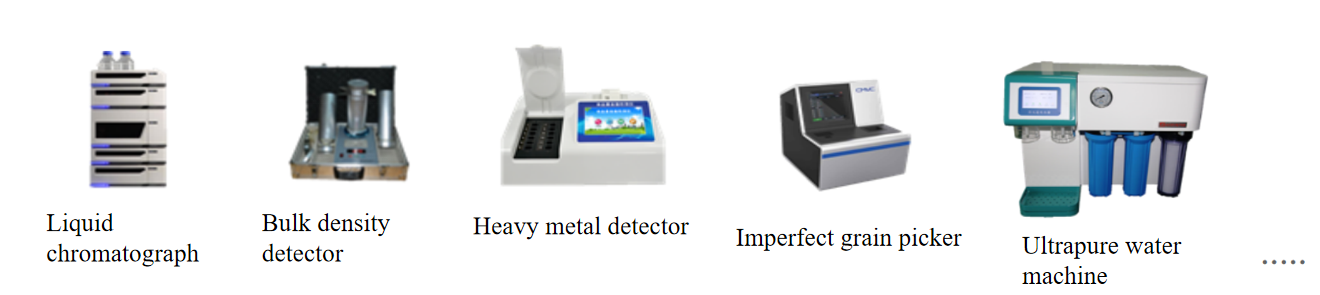

Inspection and Testing Instruments

Intelligent Security Systems

Intelligent Warehousing Equipment