The leakage control aims to reduce the gap between production and sales and improve the profit ratio. It adopts the advanced technology and management means of DMA partition measurement management, with DMA partition planning, basic sensing equipment layout, and partition metering system construction as the main contents, to achieve refined water supply management, improve the leakage control efficiency of the water supply pipeline network, and accurately control leakage.

Overall introduction

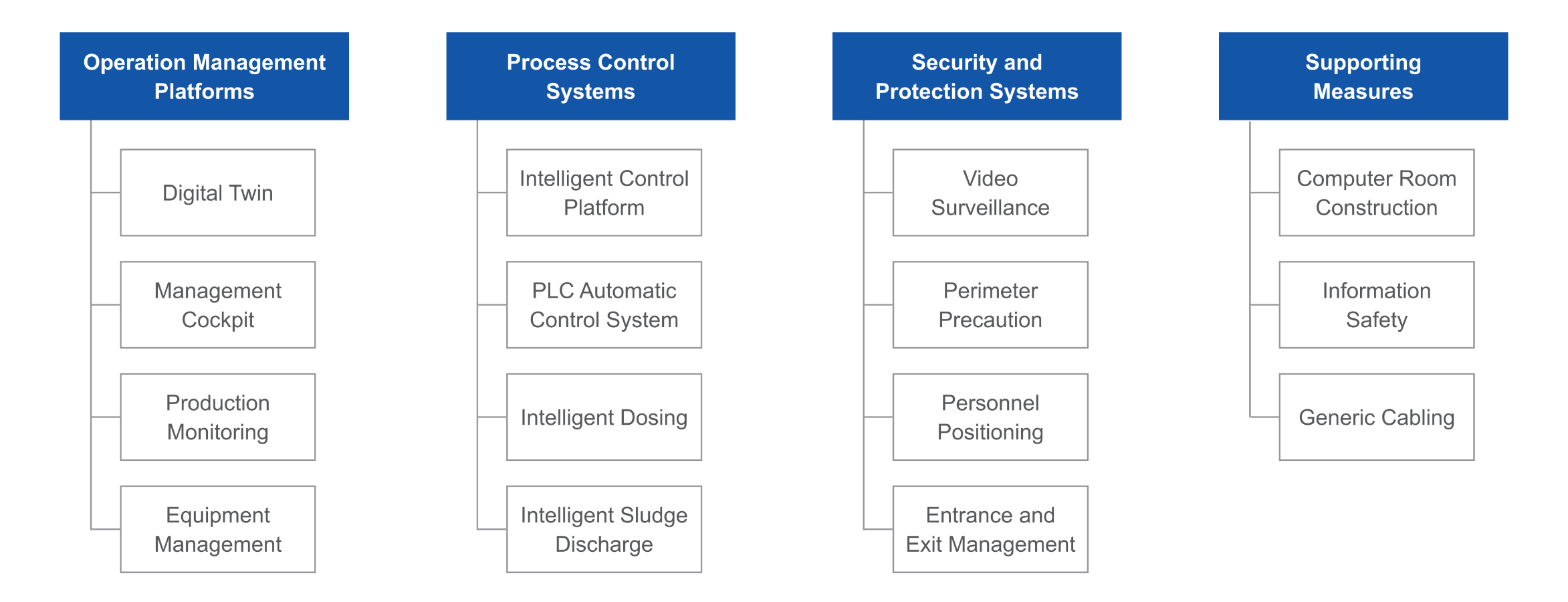

The purpose of building a intelligent water plant is to complete automation, information and intelligent multi-dimensional integrated governance and control. lt facilitates the fine management of water plants bybuilding water plant operation management platforms, implementing process control systems and safety prevention systems, and employing supporting measures, etc.

Digital twin water plant

By utilizing GIS+BIM+SCADA+IOT and other technical means to build the foundation of digital twin, realizing the real display of intelligent water plants based on the best form of three-dimensional virtual reality, integrating "physical space" and "virtual presentation", collecting real-time data in the production process of "physical space" and realizing integrated display in the "virtual" environment, the production simulation in the virtual environment and the actual production can be seamlessly integrated to promote and improve the actual production level.

Operation management platform

The intelligent production and operation control platform takes the industry's advanced technology as a benchmark, the water plant development strategy as a guide, and the improvement of performance and decision-making management level as the ultimate goal. It comprehensively develops the water plant's informatization construction, creates an advanced industry informatization platform, and comprehensively improves the company's production management efficiency and operation level.

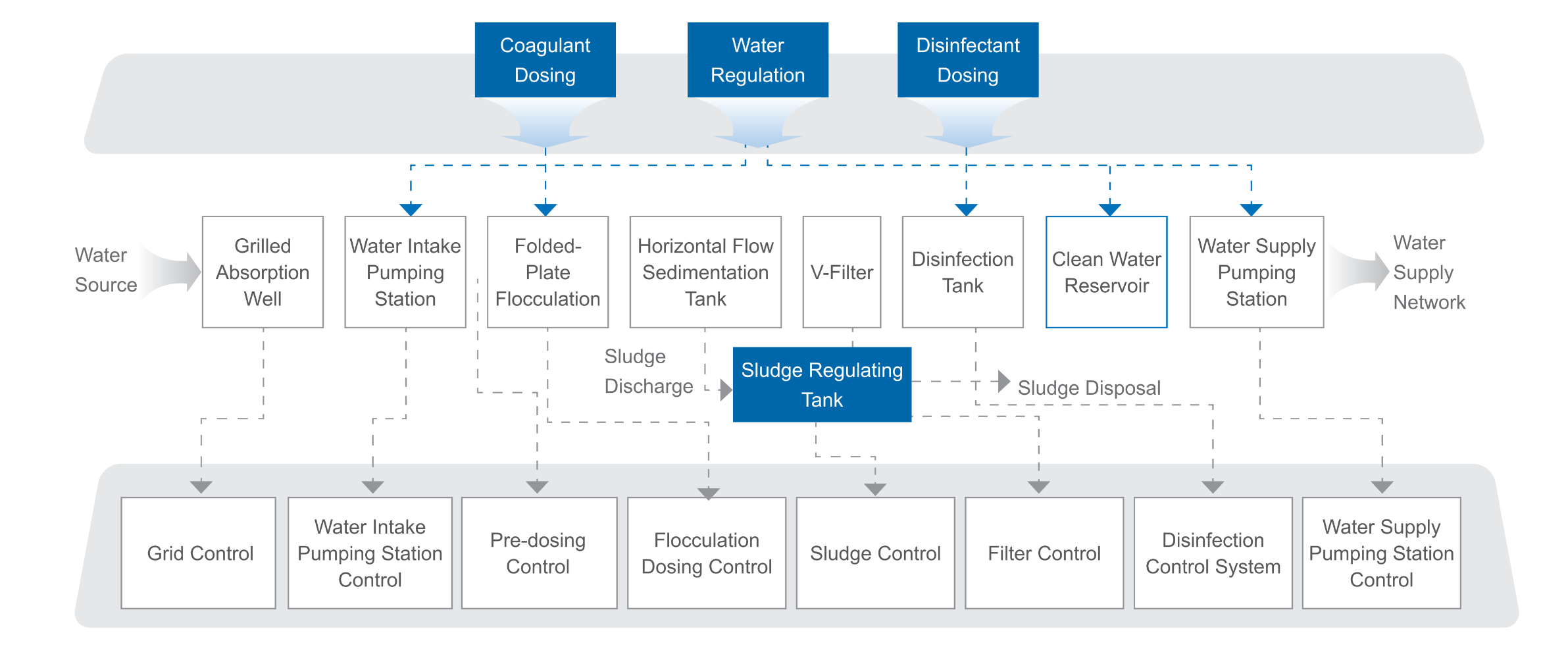

Intelligent process control

The intelligent process control of an intelligent water plant refers to the use of advanced information technologies such as the Internet of Things (IoT), big data analysis, and artificial intelligence (AI) to automate and intelligently manage the entire production process of the water plant, improve the operating efficiency of the water plant, ensure water quality safety, and reduce energy consumption and operating costs.

Security protection system

The construction of the security monitoring system is a perfect combination of access control management, video surveillance system, perimeter management, factory-wide WiFi coverage and personnel positioning system.

Realize unattended on-duty or operation with few personnel

Realizing less/unattended control and operation of water plants is the core of building intelligent water plants. Through the plant automatic control system to realize the whole process automation operation, all kinds of control instructions are no longer dependent on people, and can be completed by the automatic issuing of the system. The equipment and communication links involved in the control process adopt a redundant design to ensure automatic switching to the backup plan when equipment fails or the network is interrupted. When the process is operated intelligently, the system autonomously drives the water plant treatment equipment to achieve control targets and dynamically adjusts control parameters, so as to obtain stable and precise control effects to meet equipment operation requirements under constantly changing operating conditions. Under efficient and standardized operation and management, the requirements for human resources within the water plant can be effectively reduced, and management with less manpower at the plant level can be achieved.

Ensure water quality safety, increase efficiency, save energy and reduce consumption

By technical means such as artificial intelligence and big data, and through advanced control strategies such as models, algorithms, etc., the dosing process and pump package adjustment process can be further optimized, thereby improving processing efficiency, reducing operating costs, and ensuring water quality.

Demonstrate good operational management capabilities and corporate image of corporate in the water group

Through platform technology, the corporate's work processes are standardized and work efficiency is improved. Good compliance and efficiency reduce corporate risks and greatly enhance the company's good image.

Realize the full-process and traceable production process visualization management mode

It solves the pain points of being unable to view remote processes, production indicators, real-time on-site monitoring, and production anomalies in the past, enabling enterprises to achieve full-process, traceable remote and mobile visual management and control capabilities.

Realize a complete equipment operation and maintenance management system

It establishes electronic files for equipment, formulates a tracking and management mechanism for the entire life cycle of equipment, and establishes an operation and maintenance plan for equipment so that users can predict the maintenance period of equipment in advance. At the same time, combined with the mobile devices, it solves the difficulties of being unable to view the status of on-site equipment in real time, to check the history, and to report the abnormalities.

Achieve summary analysis of water plant KPI operation index

It improves the production and operation management level of water plants, explores the internal relationship of production indicators based on industry big data analysis, realizes the summary analysis of plant and station operation data, helps users fully control the daily production and operation of plants and stations, improves the level of refined management and effectively enhances the company's management and control capabilities.