The leakage control aims to reduce the gap between production and sales and improve the profit ratio. It adopts the advanced technology and management means of DMA partition measurement management, with DMA partition planning, basic sensing equipment layout, and partition metering system construction as the main contents, to achieve refined water supply management, improve the leakage control efficiency of the water supply pipeline network, and accurately control leakage.

Overall Introduction

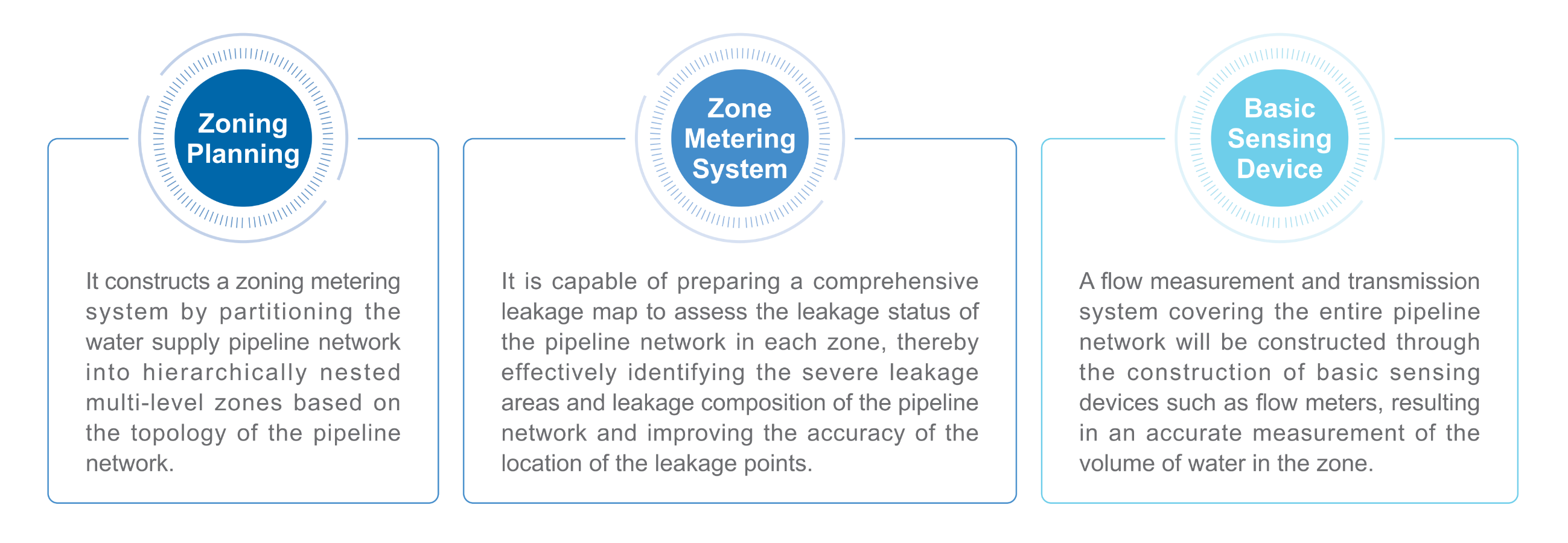

The leakage control aims to reduce the gap between production and sales and improve the profit ratio. It adopts the advanced technology and management means of DMA partition measurement management, with DMA partition planning, basic sensing equipment layout, and partition metering system construction as the main contents, to achieve refined water supply management, improve the leakage control efficiency of the water supply pipeline network, and accurately control leakage.

Partition Planning

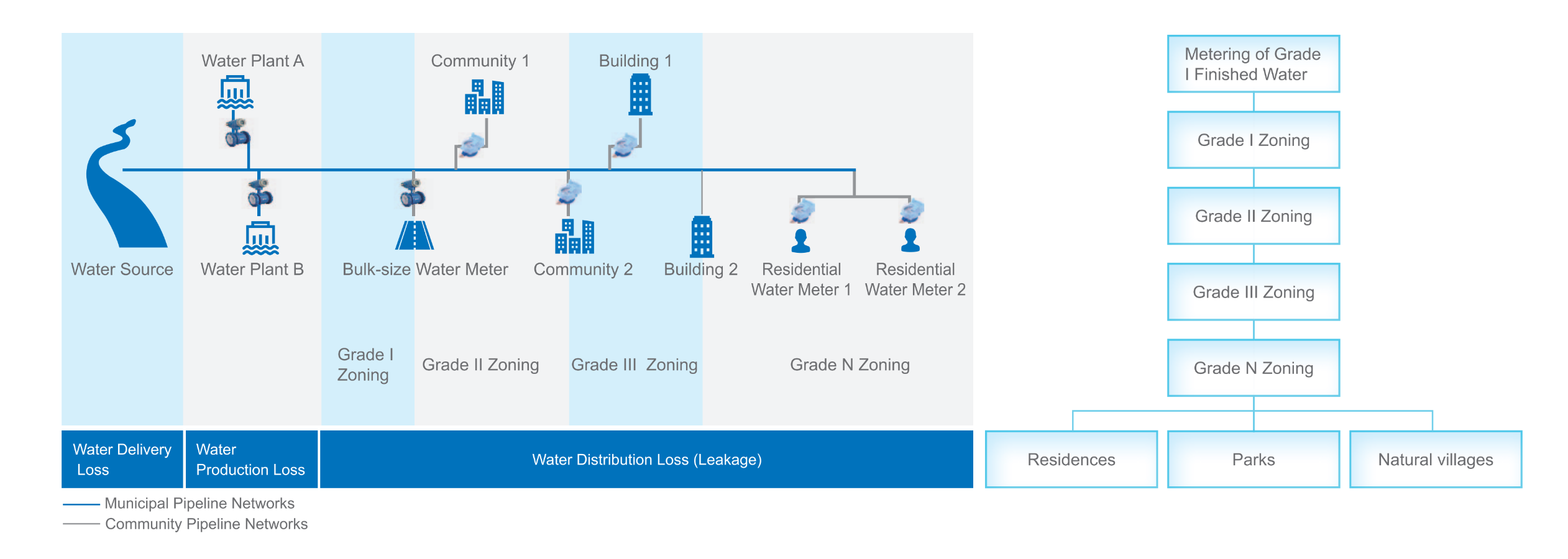

Based on the topological structure of the pipeline network, an N-level partition metering system is established to divide the water supply network into multi-level partitions nested step by step, so as to fully grasp the water volume of various types such as factory network entering volume, regional water volume, water volume in independent metering area and user water volume.

Partition metering system

It creates a leakage map, and uses methods such as water balance analysis and minimum flow analysis combined with model algorithms to evaluate the leakage status of the pipeline network in each partition, effectively identifying areas with serious leakage of the pipeline network and the composition of leakage, solving difficult problems such as inaccurate judgment of leakage areas and difficulty in finding leakage points, and scientifically guiding pipeline network leakage control operations.

Basic sensing equipment

Through the construction of basic sensing equipment such as flow meters, a flow measurement and transmission system covering the entire pipeline network is established to achieve closed management of each partition and accurate measurement of leakage rate. The main sensing equipment deployed at flow monitoring points of partitions include large-user water meters, flow meters, pressure transmitters, residential meters, and noise monitors.

Reduce the gap between production and sales

By carrying out leakage governance work, combined with leakage control service consulting and organizational architectures analyzing, it is expected that the production and sales gap can be reduced by 2%-6% each year.

Leakage monitoring

The partition metering system is used to automatically and intelligently monitor and analyze leakage, so that leakage problems can be discovered and handled more accurately, greatly reducing labor costs.

Partition measurement management

After implementing partition measurement management, the act of dividing the water supply management units into smaller units will help improve the pertinency and efficiency of management and make management work more in-depth and meticulous. For example, the methods include quickly locating the leakage problem area and improving the efficiency of problem solving, etc.

Responsibility implementation and performance evaluation

Through partition measurement management, responsibilities can be effectively implemented and work management performance can be scientifically measured. This approach solves the problems of unclear responsibilities and overlapping duties, making the evaluation of management work more scientific and performance more transparent.